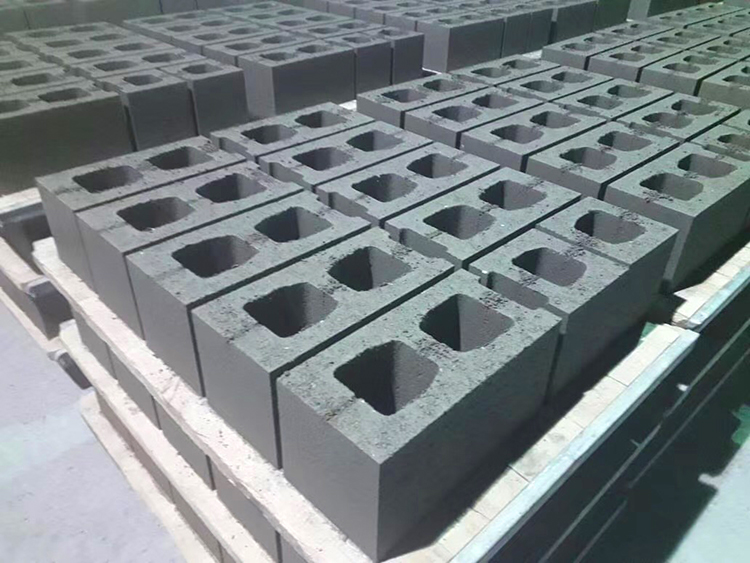

MM10-15 block making machine is one of the most popular machine for hollow block, solid block,interlocking paver, curb stone production in the market.

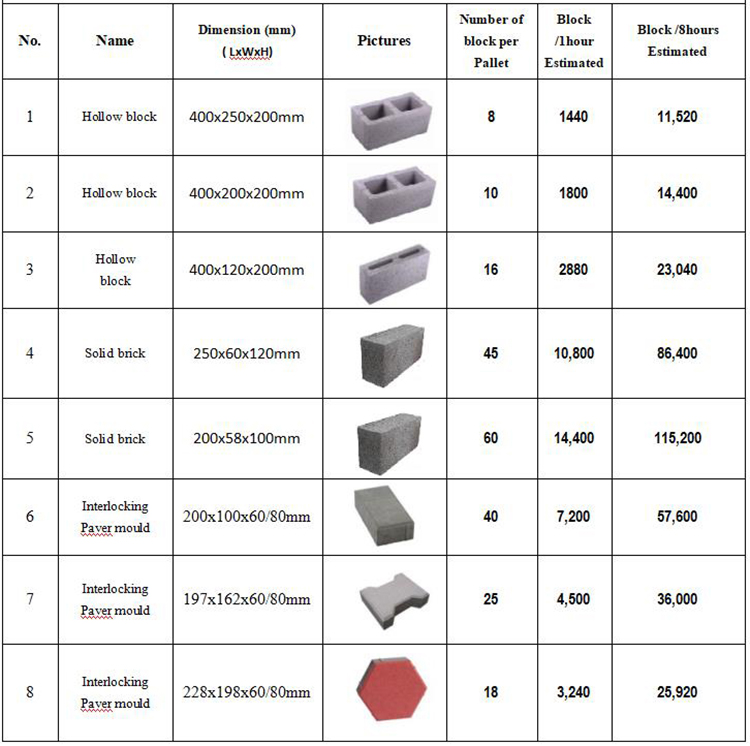

The pallet size for MM10-15 is 1100x950mm or 1100x900mm according to the size of concrete products to be made by customer.

This powerful concrete brick, block and paver making machine is capable of producing 8inch hollow block at 10pcs per drop,around 14000pcs per shift at 8 hours.

For making rectangular paver at 200x100x60mm,the output is 36pcs per drop,at 1000 square meter per shift.

MM10-15 is a well constructed block making machine features Schneider electrical parts, Japanese Yuken hydraulic valves,SIEMENS motor for hydraulic station to ensure the stable performance of plant, and the SIEMENS PLC in control cabinet,with Two SIEMENS vibration motor,ensuring the best compaction for producing the high quality brick,blocks and paver.

Vibration System Vibration table consists with dynamic table and static table. When vibration begin,dynamic table vibrate,static table remain static.The structure is designed to ensure the amplitude of the vibration table, so as to ensure the high quality of concrete products.

Feeding System

Motor use SIEMENS motors or other Famous brand Chinese motor, which control two mixing shafts. Feeding frame, bottom plate and mixing blade are made of high-duty steel, the location of bottom plate can be adjusted. The raking teeth is a complete piece bolted to the feeding cart shaft,easy to be changed during maintenance.

Hydraulic StationHydraulic pumps and hydraulic valves adopt international brands Japanese YUKEN Brand,with double proportional and single proportional valve as well as relief valve. The flow and pressure for the hydraulic can be adjusted according to different concrete block production.Tube uses "Flange Connection", convenient installation and maintenance. Multi-point pressure detection point, convenient detection. Digital temperature and blockage alarm function. Motor and pump connection, flange connection, good coaxial.