| Rated power | 250.0 HP 186.0 kW |

|---|---|

| Max.torque |

Prefer a motor grader with steering wheel and levers? The 140 uses Caterpillar’s 45 years of lever and steering wheel controls design experience to provide you with the control option you prefer.

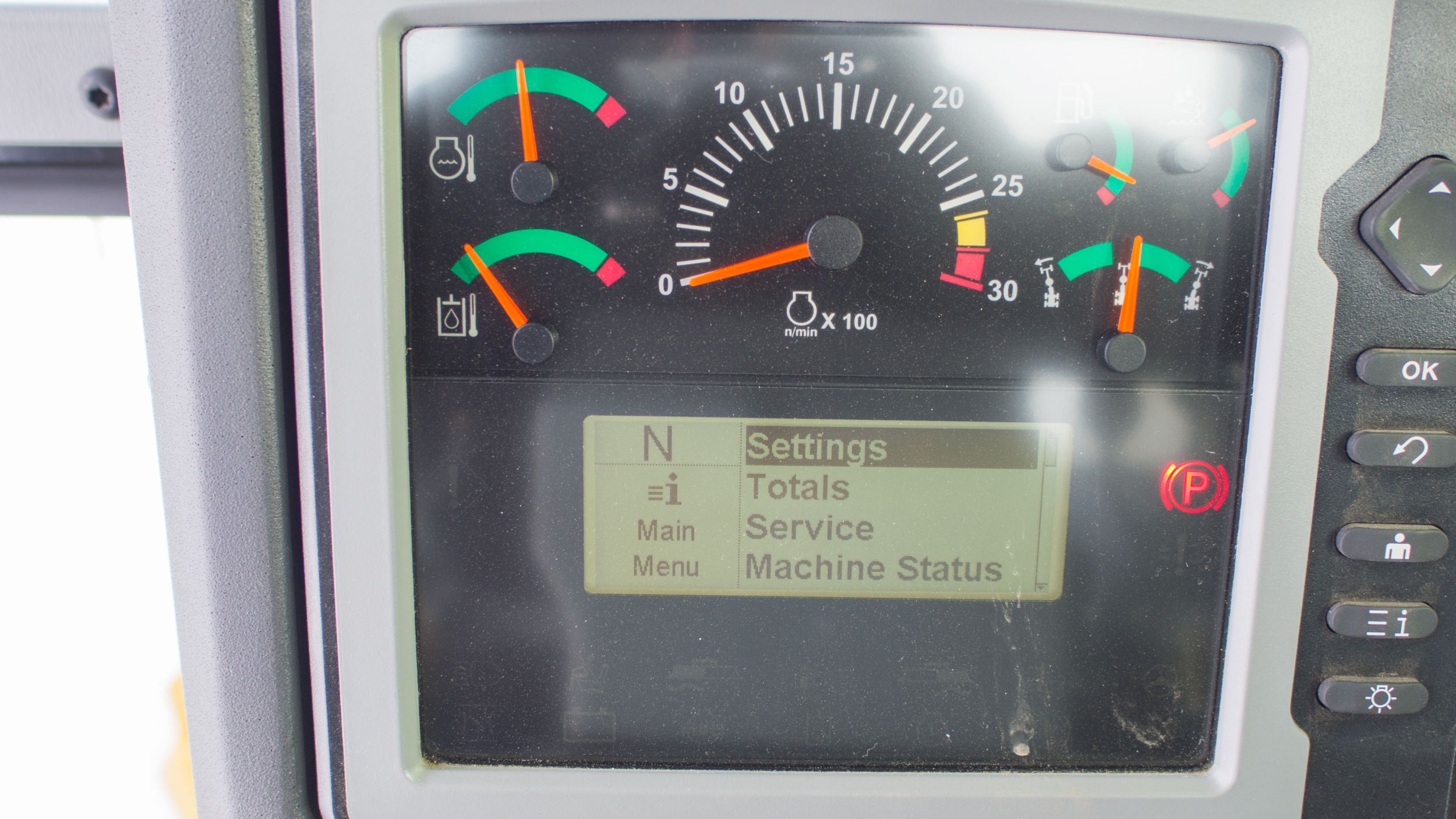

Save up to 40 percent in material with the Cat GRADE Cross Slope feature. Monitor Cross Slope information from the machine display.

Optimized machine balance ensures maximum drawbar power to the ground.

Don’t let the snow stop you from working. The all-wheel drive (AWD) option assists with traction and maneuvering the machine.

Each machine is equipped with the Cat C9.3 engine for power and reliability.

Save up to 10 percent on fuel consumption with ECO Mode.

For your fine grade applications, the hydraulic system provides multifunction capability of up to seven simultaneous functions for superior performance.

Reduce risk of impact damage with the standard circle drive slip clutch. It protects your circle drive and teeth.

Reduce your dependence on manual grade checking by using the Digital Blade Slope Meter.

Cat GRADE with Cross Slope Indicate option provides a real time readout of cross slope and can be scaled to Cat GRADE with Cross Slope for automatic blade movement.

Cat GRADE Attachment Ready Option (ARO) ensures machine readiness for additional 2D/3D grade control technologies.

Stable Blade senses blade bounce before the operator to reduce manual throttle use and site rework.

Cat Production Measurement recommends gears and engine speed to improve fuel efficiency and maintain productivity. (Coming in 2019)

Product Link™ provides location, machine hours, fuel usage, productivity, idle time, diagnostic codes, and other machine data on demand through the VisionLink® online interface, which helps you improve job site efficiency with lower operating costs.

Remote Services eliminates the need for technicians to connect to Electronic Technician (ET) to flash software updates to the machine.

Adjust to your ideal comfort with the air suspension seat with multiple ergonomic adjustments.

The rear camera option enhances visibility along with a heated lens to prevent snow buildup.

The high capacity Heating, Ventilation and Air Conditioning (HVAC) system dehumidifies and pressurizes the cab, circulates fresh air, seals out dust and keeps windows clear.

Add the communications radio mount to connect with your operators from the cab.

Filters, such as hydraulic oil, engine air, and DEF filters, are grouped together for easy access and preventative maintenance.

The new next generation filters offer up to 20 percent in reduced fluid and filter costs.

Spend less time cleaning the cooling system with the reversing fan option, which reduces costs when cleaned once per week for more uptime.

Maintain roads with the standard drawbar circle moldboard with hardened circle teeth for increased durability.

For tight finish grading, consider the top adjust drawbar option for applications that require maximum accuracy. It offers up to 45 percent reduction in maintenance cost over the standard.

Depend on your brakes with maximum stopping power on all four rear wheels.

View your work space with the rear camera option. It offers a rear view of the machine to ensure the safety of you and those around you. The dedicated display can be always on to ensure a safe work environment

In the event of an engine issue, your operators can count on the secondary steering system to stop the machine safely. It turns on automatically if the main pump pressure drops.

Ground level refueling requires no climbing on the machine to fill the fuel tank.

Ensure three points of contact when entering and exiting the machine with strategically placed walkways and grab rails.

Work past sundown using the LED light option for increased nighttime visibility.

Ripper and Scarifier options are available.

Improve the balance of your machine with the counterweight and push block for increased performance and efficiency.

For snow applications, straight blades or v-plows added to the front lift keep roads clear.

Plow through snow with the mast-type or mast-less snow wing attachment.

For more road coverage, add a moldboard extension to add 600 mm (24 in).

The Cat® 140 Motor Grader combines technology and lever controls for high performance. Integrated technology, such as Cat GRADE with Cross Slope and Stable Blade options, ensures optimal grade for your project. The new cab offers increased comfort and ergonomically designed, adjustable control console. Reduce up to 10 percent fuel consumption by using ECO Mode and 20 percent in fluid and filter maintenance costs with the new filtration technology.

Units:

| Torque Rise - ISO 9294 | 44% 44% | More |

| Bore | 4.5 in 115.0 mm | More |

| Displacement | 567.5 in³ 9.3 l | More |

| Emissions | U.S. EPA Tier 4 Final/EU Stage IV U.S. EPA Tier 4 Final/EU Stage IV | More |

| Engine Model | Cat C9.3 Cat C9.3 | More |

| Engine RPM | 2,000 2,000 | More |

| Net Power - EEC 80/1269 | 250.0 HP 186.0 kW | More |

| Net Power - ISO 9249/SAE J1349 | 250.0 HP 186.0 kW | More |

| Number of Cylinders | 6 6 | More |

| Standard Capability | 109.0 °F 43.0 °C | More |

| Stroke | 5.9 in 149.0 mm | More |

| Weight* | 42.325 lb NaN kg | More |

| All-Wheel Drive (AWD) Weight | 44.613 lb NaN kg | More |

| Note | *Typically equipped with push block and ripper. *Typically equipped with push block and ripper. | More |

| Blade Width | 12.0 ft 3.7 m | More |

| Arc Radius | 16.3 in 413.0 mm | More |

| Cutting Edge | 6.0 in 152.0 mm | More |

| End Bit | 6.0 in 152.0 mm | More |

| Throat Clearance | 6.5 in 166.0 mm | More |

| Maximum Depth of Cut | 28.9 in 735.0 mm | More |

| Maximum Lift Above Ground | 18.9 in 480.0 mm | More |

| Basic Blade Width | 140.0 in 3556.0 mm | More |

| Length of Machine* | 397.6 in NaN mm | More |

| Maximum Height | 132.0 in 3354.0 mm | More |

| Note | *Typically equipped with push block and ripper. *Typically equipped with push block and ripper. | More |

| Width | 97.6 in 2480.0 mm | More |

| Circle Drive | 1.8 gal (US) 7.0 l | More |

| Engine Crankcase | 7.9 gal (US) 30.0 l | More |

| Front Wheel Spindle Bearing - Each | 0.13 gal (US) 0.5 l | More |

| Fuel Tank | 100.0 gal (US) 378.0 l | More |

| Hydraulic System | 14.5 gal (US) |

CATERPILLAR

Name : Cat

Service Tel : (309)578-6298

E-mail :

Web Site : https://www.caterpillar.com/en.html

Address :

Copyright Notice 2002-2019 global-ce.com Construction Machinery Online. All rights reserved.

Address: Room 901, Building C, Ruipu Mansion, Hongjunying South Road No.15, Chaoyang District, Beijing.100107 P.R.China